Air Receiver Tanks

Design, create, and deliver vertical and horizontal air receivers with the Midwest Tank team.

Your Guide For Air Receiver Tanks

When inquiring, please indicate:

- Volume

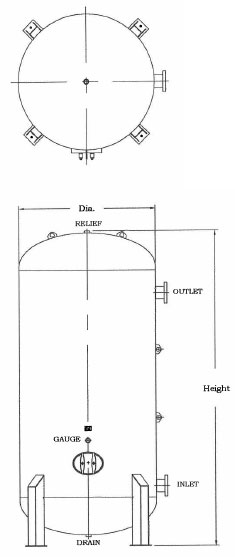

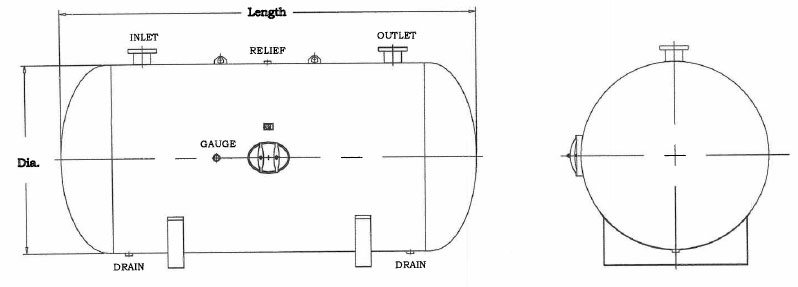

- Vertical or Horizontal

- Available space so that we can size the tank accordingly with a diameter and height necessary to meet the volume required and the space available.

- Size of inlet and outlet

- Design pressure of the vessel

- Painting requirements

- Exterior

- Interior

To make things easier, please fill out the information on the Air Receiver sketch and send it to us for quoting purposes. Once an order is placed, Midwest Tank Co. will provide a detailed drawing for approval.

| Item # | Capacity | Inlet Size | Outlet Size |

|---|---|---|---|

| AR-100 | 100 gal | 3 in | 3 in |

| AR-250 | 250 gal | 3 in | 3 in |

| AR-500 | 500 gal | 3 in | 3 in |

| AR-650 | 650 gal | 3 in | 3 in |

| AR-750 | 750 gal | 3 in | 3 in |

| AR-1000 | 1000 gal | 3 in | 3 in |

| AR-2000 | 2000 gal | 6 in | 6 in |

| AR-2500 | 2500 gal | 6 in | 6 in |

| AR-3000 | 3000 gal | 6 in | 6 in |

| AR-4000 | 4000 gal | 6 in | 6 in |

| AR-5000 | 5000 gal | 6 in | 6 in |

| AR-6000 | 6000 gal | 6 in | 6 in |

| AR-8000 | 8000 gal | 8 in | 8 in |

| AR-10000 | 10000 gal | 8 in | 8 in |

| AR-12000 | 12000 gal | 8 in | 8 in |

| AR-15000 | 15000 gal | 8 in | 8 in |

| AR-20000 | 20000 gal | 8 in | 8 in |

We con build larger or custom sizes to meet your specifications.

Contact Us to Discuss Your Requirements.

Air Receiver Tank Applications: Boost Efficiency with Midwest Tank Co.

Air receiver tanks are vital across industries, optimizing compressed air systems. At Midwest Tank Co., our ASME-certified tanks enhance performance in key applications. In manufacturing, they store air for pneumatic tools, stabilizing pressure for consistent operation—think assembly lines or robotics. Construction relies on them to power drills and jackhammers, buffering peak demands on-site.

In water filtration, Midwest Tank Co.’s large air receivers support infrastructure, ensuring steady air supply for treatment processes. HVAC systems use them to manage air pressure, improving energy efficiency in cooling towers—our custom tanks fit unique specs. Automotive shops depend on them for spray painting and tire inflation, reducing compressor wear.

These tanks—built to ASME Section VIII standards—cut moisture, boost dryer efficiency, and store dry air post-filtration. From hydropneumatic setups to cooling tower sump tanks, Midwest Tank Co. crafts carbon or stainless steel solutions for your needs.